Down is the world's most warm filling material and made of animal protein, it is natural and light. Therefore, down quilts have become the preferred bedding for consumers. The popularization rate in Europe and the United States reaches 60% and the utilization rate in foreign luxury five-star hotel is above 80%, and the popularization rate in Japan has reaches 100%(1.3 quilt for per person), from which we can tell that down has become the symbol of high quality sleep.

On the market, the inferior down is crushed down to be used as good down, which has no good warmth retention and air permeability. Due to the lack of high-temperature sterilization procedures, it is easy to produce odor and bacteria and has the potential risk. Do you dare cover it to sleep every day?

How to choose the high quality down quilt? [Chuangyu down] tells you the four secrets.

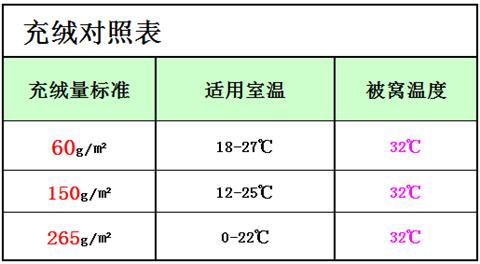

[Secret One] the filling power and temperature of bed is 32℃

Filling power is the important index to measure warmth retention, refers to the numerical volume of cubic inch that every ounce (30 grams) down occupies in a certain condition. The filling power is higher, the warmth retention is better, which means the down in the same filling amount can hold more air layer to keep warmth and preventing heats. Currently, the filling power of the down quilts on market is 500-600 and the one of Chuangyu's gold down quilt has reached 800.

High quality sleep can eliminate a whole day's fatigue and makes people energetic. So, what is the most comfortable temperature to sleep? Let's find out the secret of 32 degree!

To ensure the high quality of sleep, in addition to the influence of environment, we need to pay attention that micro environment formed by human body, the quilt, mattress, pillow and other beddings, which can be understood as the temperature of the bed. That thee temperature is too high will cause the excessive sweating, the water loss of human body and the breeding of bacteria. It is too low will lead to the self protection of the body, interrupts the normal sleep and reduces the quality of sleep!

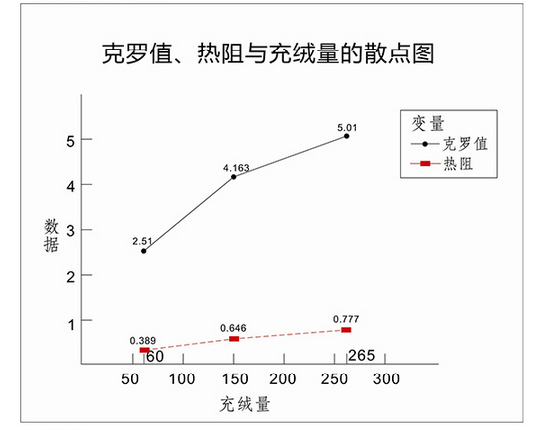

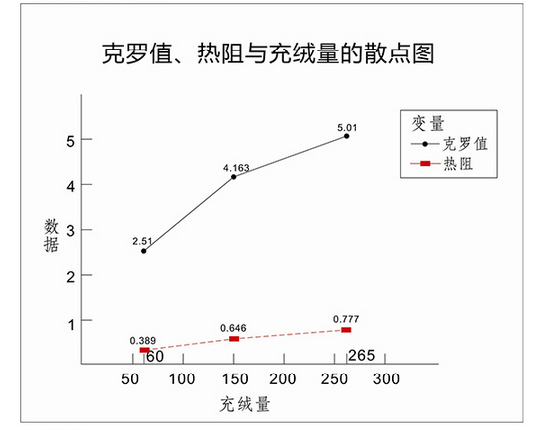

In order to improve the quality of sleep, Chuangyu makes a test experiment: make a quilt with the size of 40X40CM, then fill three ones with 9.6g,24g and 42.4g(the filling powder is 800), mail these to Guangzhou Fiber Inspection and Test Institute to test. The figure is obtained as below.

Conclusion:

1. With the increase of filling quantity, the values of clo and thermal resistance increase, namely the warmth retention is better.

2. After it reaches a certain value, the increase of filling quantity, the values of clo and thermal resistance don't change much.

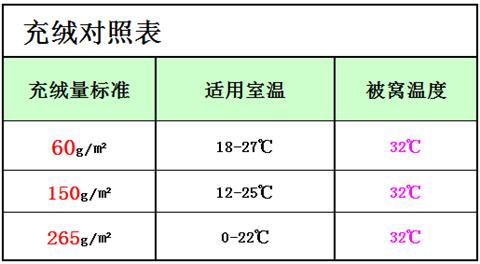

Through repeated experiments, the comparative table of best filling amount of down quilt:

According to the experimental results, Chuangyu produces down quilts to meet customers' demands from different areas according to the production standard, letting them feel the high-quality comfortable sleep of 800 filling powder and 32℃. In the past 30 years, we only focused on the down quilts and gave the best quality to everyone.

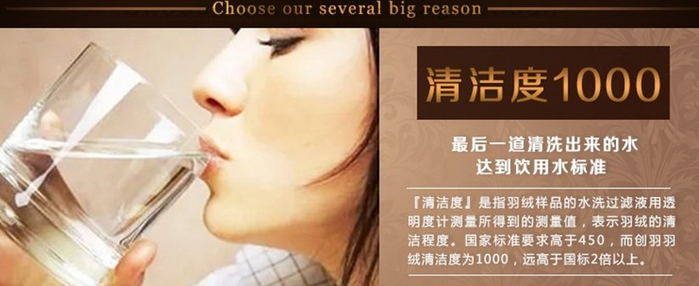

[Secret Two] Dust and health

People spend 1/3 of the life time in sleep, high quality of sleep for everyone is very important, comfortable sleep keeps people away from fatigue and makes them energetic. With the improvement of the quality of life, light and comfortable down quilts are entering into millions of households and the popularity rate is getting higher and higher.

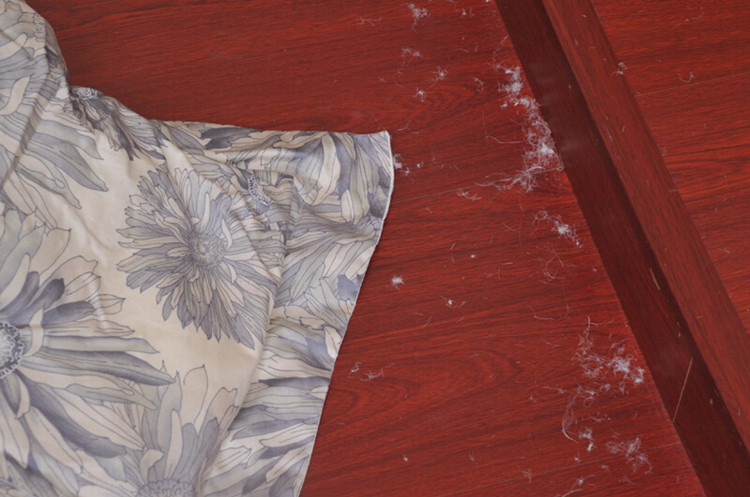

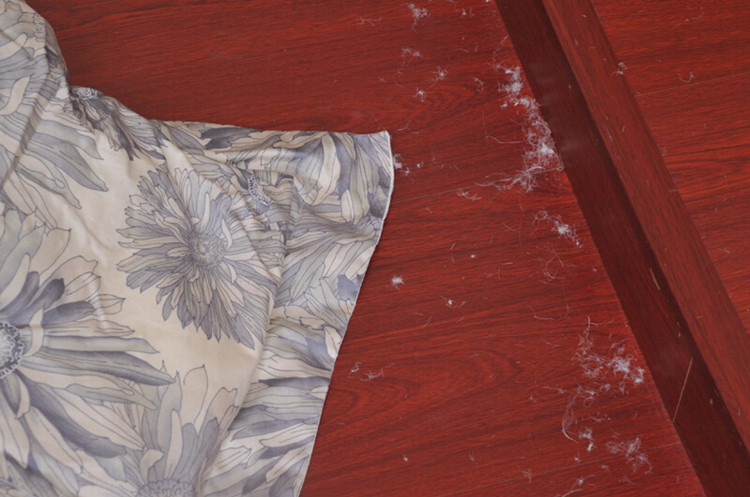

But there are more and more inferior down on market and some unscrupulous merchants use the smashed features as down. A lot of dusts are produced when smashing the feature, which are filled in the quilts with the inferior down.

The picture is the dust of inferior feathers

The dusts is very harmful and can enter the human respiratory tract with breathing, some are into the alveoli or stay in the respiratory tract from the nasal cavity into the alveolus, which are easy to cause cough, asthma and respiratory tract infection diseases. The quilt is the items that closes to human body, it will do great harm to personal health for people if people cover the down quilt with dusts in the long term.

So, how to tell distinguish the down quilt without dusts? Consumers beat the quilts in the sunlight while purchasing, watch whether there are dusts flying out, especially the places of suture.

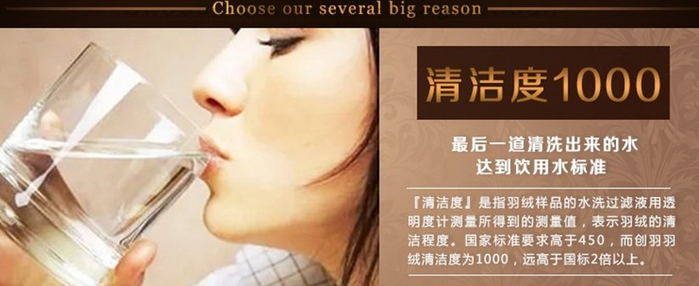

In order to solve the problem of dust, Chuangyu has a major breakthrough after 30 years of development and innovation, 30 washing down processes, washing one ton of down needs 800 tons of water, the unique green washing disinfection technology, after the 12 minutes' 130℃high temperature anti-virus processing, the cleanliness can reach 1000mm(national standard is 450mm). The down quilt with such cleanliness has zero dust.

In order to let everyone see the dust of down quilts, we deliberately use the dust instruments to test Chuangyu down quilt and the one on market, and record it with HD camera.

(The left is Chuangyu 95% white duck down, the right is 95% white duck down on market)

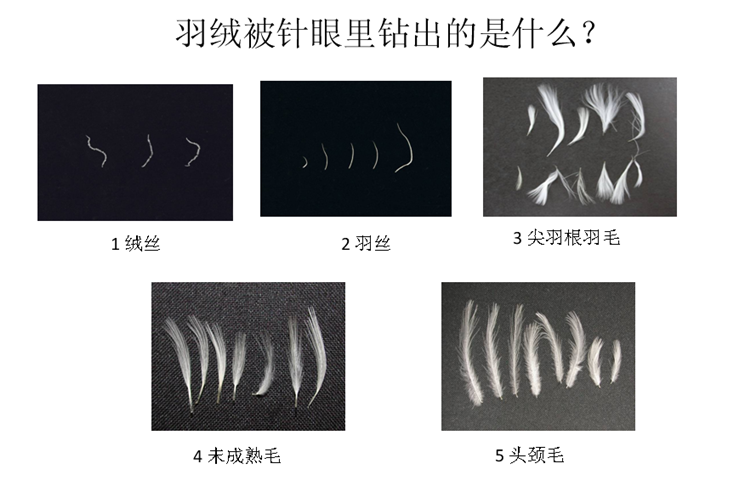

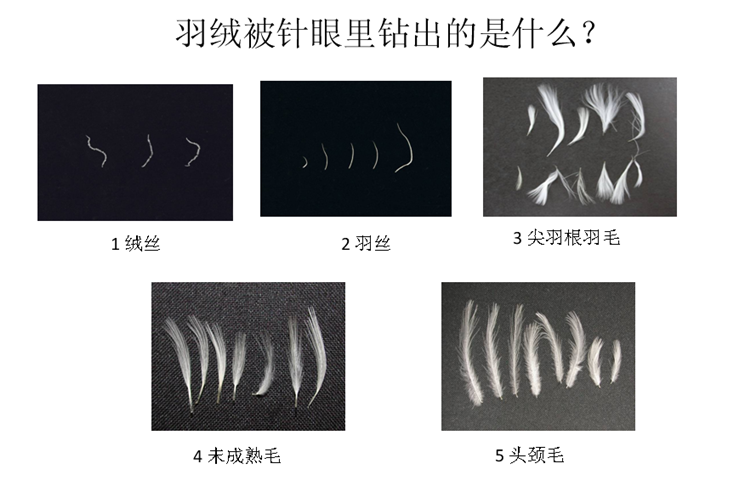

[secret Three] down running and feather fiber and down fiber

Down running is the most common problem, some quilts have the serious problem and people look like from chicken coop. The problem mainly has two related elements. The first is the fabric, because the density of the materials is not high, so the effect to preventing the down is poor. The most important reason is the quality of down. Inferior down has a lot of feather fiber and down fiber, even the fabric with more intensity will have the problem.

Feather fiber also known as Dansi and is the silk left by down in cleaning and product process. Down fiber is also called Feisi, is the silk fallen off from down flowers. Because these are the natural materials, these can be used the fillers of down products. General speaking, the down fibers that fall off naturally is limited and the ones in cleaning and production process will not affect the quality of products. But some bad business companies smash the feathers into the shape of silks directly by artificial processing. The length of the silk is 2-3 cm, people can easily find that it is the smashed feathers. Although we cannot touch the hard stems, the small feathers are harder than down like a small needle. Even the fabric is 100% anti-silk, these little Feisi and Dansi flying in the air and are breathed by customers, which are harmful to their health.

In this regard, Chuangyu always sticks to the gold 6 hours in the process of collecting the raw material.

1. Collect feathers and send it to the factory within 6 hours after the ducks are killed, then dry the raw materials.

2. Air and release the heat for over 12 hours after the drying.

The above two steps is to avoid the bacteria produced by the wet and heat raw materials, which will cause the brittle down silks and the separation with down cores and produce a lot of Feisi. So, Chuangyu down has a little of down silks and Dansi after processing, and the down content can reach 95%. The high content, less than 3% of Feisi and Dansi, the fabric that Chuangyu developed with fabric manufacturers, the high-intensity fabric, large calender's Processing and ironing, blocking the weaving holes, all these make the best effect against down running. The fabric has a certain permeability and soft hand feeling, highlighting the soft and comfortable feelings of down quilts.

The figure is the fabric drilling cashmere performance tester, we make two samples with the size of 60*60cm, according to the common down quilts and put these in the tester. Through the device mocking the anti drinking down performance under the external forces. The device turn 1000 times in the right and the opposite directions, there are 10 solid balls that can complete the different trajectories in multiple directions, which can maximizes mock of the wear tests. It can reflect the performance scientifically and visually. After the tests, there is no down silk and Dansi coming out from the surface of down quilts or no ones are found in the inside of the device.

According to the industry standard requirements of QB / T 1193-2012, the down-proof performance/silk≤20, after the test, there no down silk and Dansi out from the Chuangyu down quilt, which are far higher than the industry standard.

[Secret Four] fabric and air permeability

A high-quality down quilt has have the down-proof fabric, and the air permeability of the processed fabric is very important. If the permeability is big, there will be the problem of down running. If it is small, the air won't go through, which will cause the over heat of the bed and reduce the quality of sleep.

The down-proof processing of the down quilts have two types: coating and calendaring.

Coated fabric are used the silk, cotton, washing cotton with high-intensity warp and weft yarn. Processed by the rolling pressure, the gap between warp and weft yarn is narrowed, and then coat the high molecular size, form the transparent coating layer to seal the gap. The coated fabric has a good down-proof effect, but the layer cause the bad permeability. Covering it for a long time, people will feel the heat, and the coating fabric will make the rustling sounds, which has a certain influence on sleep.

Calendering fabric is a kind of textile products with high intensity in the horizontal and vertical directions, after the processing, ironing and blocking the holes by the large calender, it has a good down-proof effect. At same time, the fabric has minimal permeability, good feeling and softness. So, the down quilt with the fabric is the most comfortable and is favored by customers.

Chuangyu cooperates with fabric manufacturer to develop the exclusive fabric for down quilt. The high cotton content, high-density fabric, good scalability and good air permeability make the quilt more soft, comfortable and luster, so the quilt is welcomed by customers.

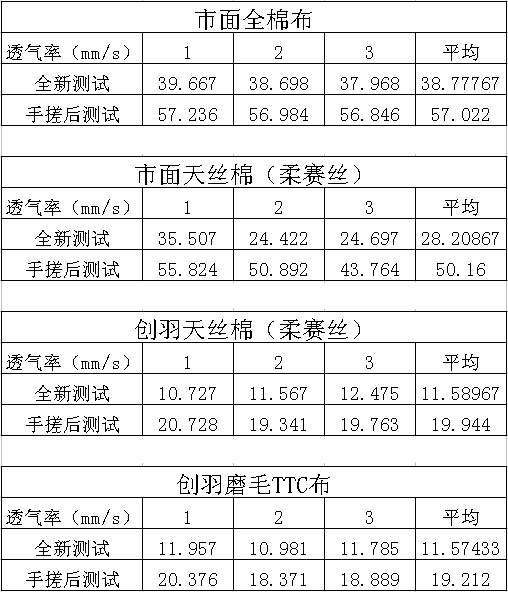

Permeability of fabric and the down-proof effect are the most important two indicators of down quilts, we deliberately do the experiment to contrast Chuangyu fabric and the fabric on market. In the same conditions, the follow data is obtained:

Note: 1. The four fabrics are measured for 3 sets of data and pick the average value of air permeability rate.2、2. The new test represents air permeability of the newly bought fabric, hand rub test is to mock the rate after it is used in a period of time.